Product

Our product

YOUR WASTE WATER SOLUTION!

Water Cleaning Treatment Systems from all sources

- Cities & Municipalities

- Commercial/Residential

- Industrial

- Hogs/Poultry/Cattle

Our product is a breakthrough technology that is able to treat all kinds of organic waste, including residential, commercial, industrial, and municipal sectors. It can be effectively used in natural waterways such as rivers, lakes, and bays. Unlike other water cleaning treatment systems, our cleaning system constantly produces its own good microbes, eliminating the need to add new microbes everyday. The microbes are all-natural and have not been genefically modified.

They are safe from pathogens or from the risk of mutation. Only microbes classified by the US Center for Disease Control and Prevention (CDC) as BioSafety Level 1 are used in our product.

Features

● Reduces Biological Oxygen Demand (BOD)

● Produces zillions of Microbes and the aeration mixes them evenly.

● Reduces cost for pond maintenance and mixes up to 5m of depth.

● Eliminates foul odors and aerates up to 2500 sqm.

● Eats sludge fast and uses less than 2.5Hp per unit.

● Easily moved to another spot for wider coverage.

● Easy to assemble and operate on site.

● Cuts electric bills by 75% compared to others traditional system.

Specification

1. Aerogrid is made of injection molded HDPE plastic and comes with 66 feet of Aerotube aeration tubing attached using stainless steel clamps. The size of this grid is 1m x 1.2m.

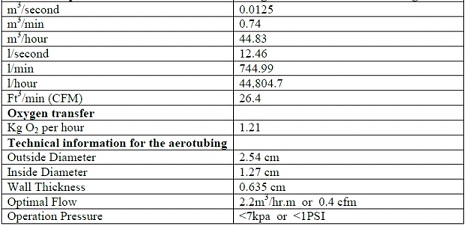

Air flow requirements

Per Grid (Full unit has 3 grids)

2. Biotubes are microbial bioreactor made of perforated stainless steel cylinder. It is 3 meters in length and 4 inches in diameter. This Biotubes are filled with “medias” that are full immobilized microbes. Aeration diffusers are also located in the entire length of the Biotubes to provide oxygen to the microbes with 55 watts air blower.

3. Fiber glass angle bar are framings that is 2inch x 2inch x 3mm in size. This is light weight and heavy duty bars that can be submerged in to almost any contaminant water.

4. PE plastic walls are to cover about ¾ of the lift; it is composed of four sheets that is 3.28ft x 2ft x 2mm. This is to provide water direction and suction.

5. Floaters are made of PE plastic that is 61 inches in length, 12 inches in width and 8 inches in height.This will provide buoyancy to the Biocleaner, making it mobile and use less power.

6. Air Blower is a single phase motor that uses 1.75kW of power. This motor will transport 240m3 air/hr. Approximately 3.65 kg O2/hr are transferred in to the surrounding water.

Full Size Unit

How it Works

The machine can break down unwanted waste leaving no sludge at the fastest rate with the lowest carbon footprint. This innovative process has undergone years of critical research and development in the United States and was crafted to even surpass international regulatory standards treating waste water down to BOD

We can treat water down to recycle grade (irrigation, boiler re use, cooling towers, washing water) and even to drinking with Reverse Osmosis (RO Membranes). This means that other criteria such as TSS and TDS can also be treated down to Not Detected (ND) if we design to in such a way.

Our product’s waste water cleaning method is so effective that it produces clear and odorless water, eliminating the need for chlorination that can be harmful to the environment. It also employs different Biosafety Level One microbes to treat different kinds of waste streams. The product’s compact form can be easily fitted in existing sewage treatment plants that allows other facilities to benefit from its advantages making it the easiest and most economical solution to all water cleaning needs.

It also delivers a very efficient amount of oxygen to the water transferring 3.6 Kgs of oxygen per hour, enabling the microbes to have a good source of oxygen.